The Heart and Soul of the blade= The STEEL

Current steels in use- Vanax, Magnacut, 8670 TUFF, LC200N, S90V, CPM S110V, CPM REX 76, CPM 20CV, AEB-L, D2, 440C, 1095, 52100

In the custom knife making world it is common for makers to select a few particular steels and use them in an almost exclusive fashion. There are a number of good reasons for this, and one of those reasons is to master the heat treatment of a few particular steels to maximize those steels potential.

At Creely Blades we are steel junkies, and we believe we are in the middle of a golden age of modern steel manufacturing. As such our blades will employ a range of steel from the nostalgic 440c, D2, and 1095 to the modern exotic powdered steels from CPM and Carpenter. It would be nearly impossible for a small shop like ours to master heat treating the number of good steels that are available today. We send our blades to one of the top heat treatment operations in the country. Blades are treated in a vacuum furnace, deep cryo treated (-300 F), and triple hardness tested to verify that they are at the desired Rockwell rating. This approach will allow us to satisfy our own inner steel junkie, and maybe yours as well!

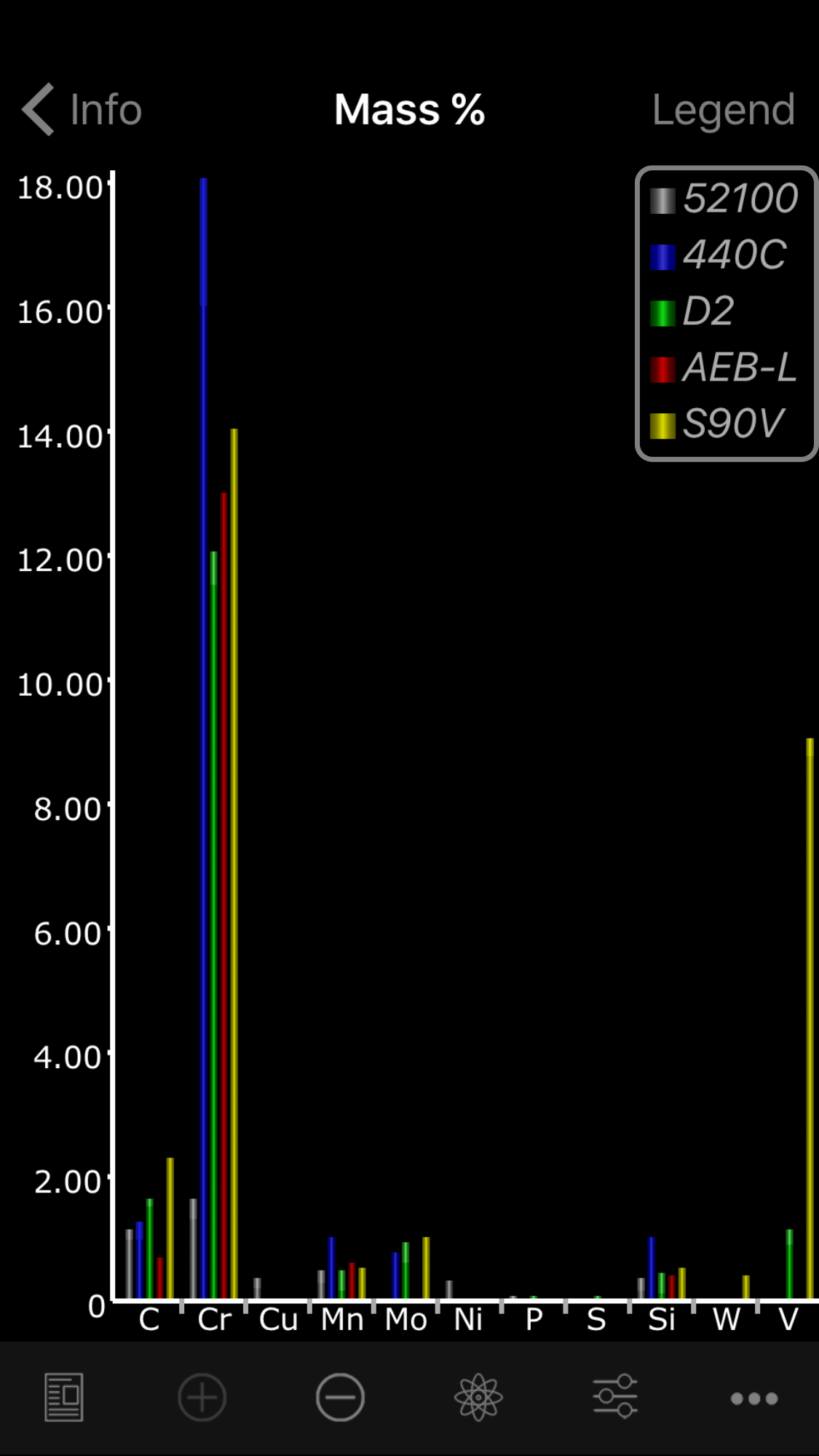

Blade steels fall into 2 primary camps, carbon steels and stainless steels (sometimes called high carbon stainless). Those categories could be broken down further into simple carbon steel and tool steel. Tool steels would have additional alloying metals in their recipes were simple carbon steel don't have much more than iron and carbon. We use steels out of most of these categories.

The steels we are most commonly using at the moment:

AEB-L- This is a German steel that is very common in disposable razors. AEB-L was originally developed for razor blades. Sandvik copied AEB-L and calls it 13C26. These steels are formulated with just enough carbon for the steel to get very hard but not make any chromium carbides. The extreme fine grain makes them easy to sharpen, have good edge holding and excellent edge stability. More custom makers have taken a liking to this steel, and kershaw uses the sandvik version of this steel for their base USA produced models.

440c- This is the super steel of your father's generation. For many years it was the king of all stainless steels, and even today it is a good steels when well heat treated along with cryo. It should not be confused with other 400 series stainless steels like 420, or 440a/b as these are inferior to 440c. 440c is the base recipe for cm154, cpm154cm, RWL34, and ATS34. There are slight alterations to the recipes and difference the metal manufacturing that make those modern steels slightly better than 440c, but they are very similar. Buck knives used 440c until the mid 80s when they switched to 420HC (a lessor steel).

52100- Originally developed for industrial ball bearings 52100 has been fast becoming a very prefered carbon steel amoung custom makers. It has excellent edge retention with good toughness. Because it is a carbon steel it does not have a significant amount of chrome, and as such it needs to be cared for or it will rust.